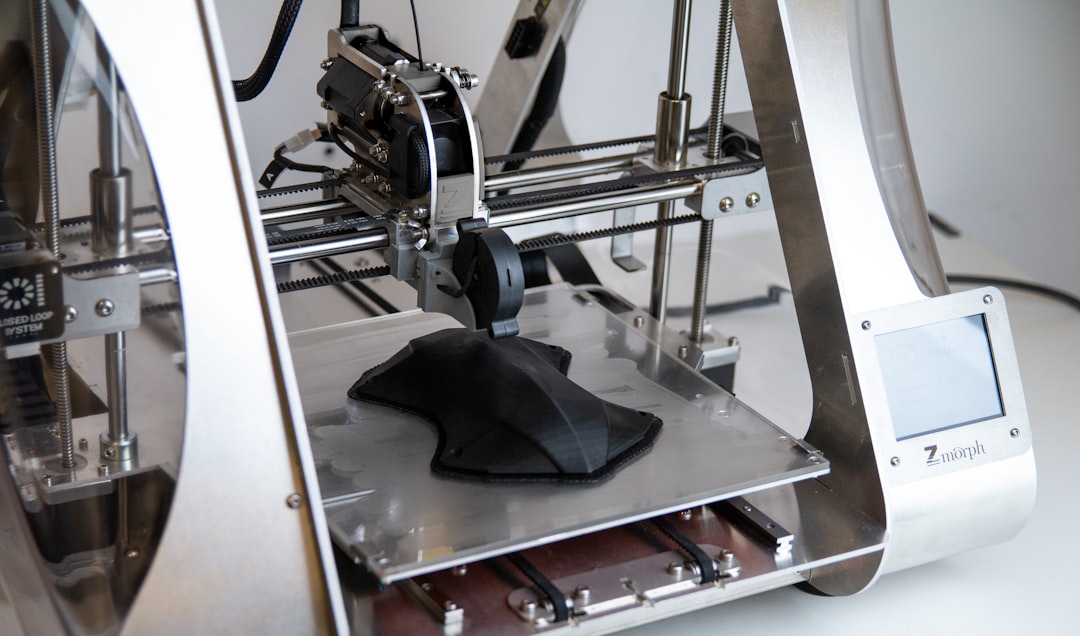

As 3D printing technology continues to evolve, dual extruder 3D printers have become increasingly popular among hobbyists, professionals, and small businesses. These advanced machines offer the flexibility to print with two different filaments or colors simultaneously, enabling more complex and visually dynamic prints. But with so many options on the market, how do you choose the right dual extruder 3D printer for your projects?

Understanding Dual Extrusion Technology

At its core, a dual extruder 3D printer has two print heads that can either work together or independently. This versatility unlocks several benefits:

- Multi-material printing: Combine rigid and flexible filaments or experiment with dissimilar materials.

- Two-color printing: Add color contrast to your creations.

- Soluble supports: Use water-soluble filament for easier support removal and cleaner prints.

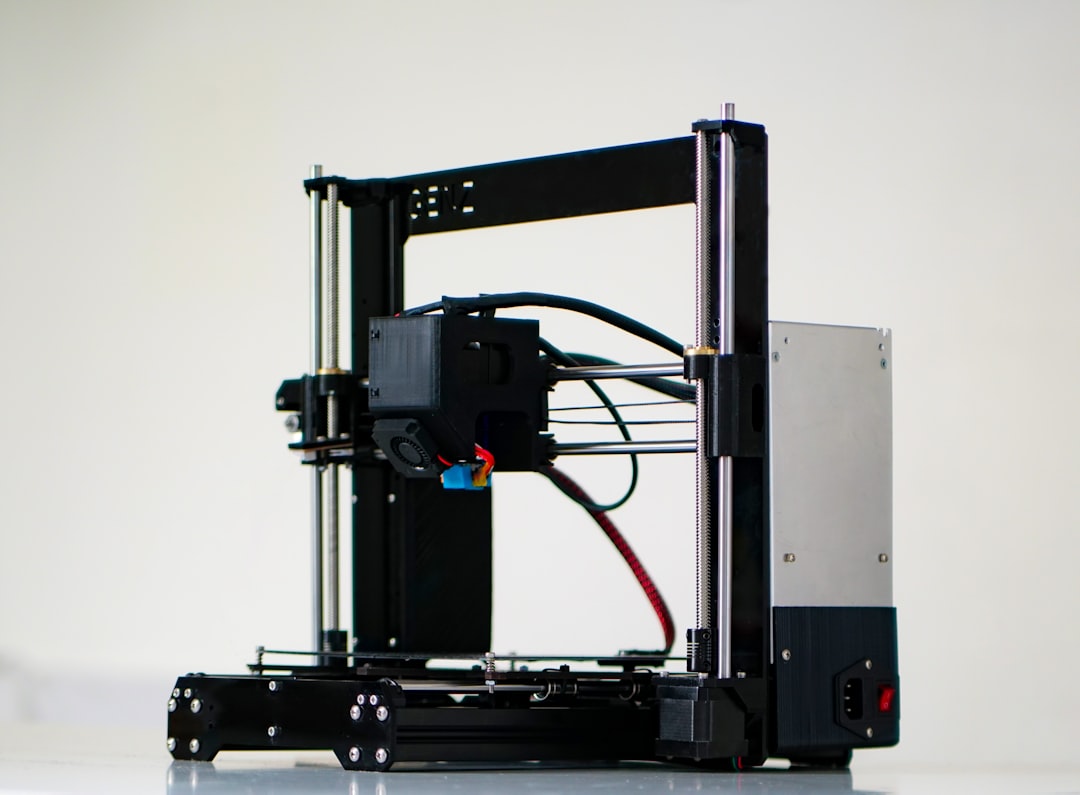

There are two primary types of dual extrusion systems:

- Independent Dual Extruder (IDEX): Each extruder moves independently, ideal for mirror or duplicate printing.

- Single Carriage, Dual Nozzle: Both nozzles share the same carriage, more affordable but may have alignment issues.

Key Considerations When Choosing a Dual Extruder 3D Printer

To select the best machine for your needs, evaluate the following factors carefully:

1. Print Volume

One limitation of dual extrusion is that the second extruder often reduces the available build volume. Make sure the machine can accommodate the size of your typical projects. If you work on large prototypes or parts, this is especially important.

2. Filament Compatibility

A good dual extruder printer should handle a variety of filament types such as PLA, ABS, TPU, PETG, and specialty materials like HIPS or nylon. Check if the printer has all-metal hotends and a heated bed to expand your material options.

3. Extruder Design

Decide between an IDEX system or a dual-nozzle setup on the same carriage. IDEX offers higher precision and more flexible printing options but can be more expensive. Dual-nozzle systems are cheaper but more challenging to calibrate and maintain.

4. Software Support

Ensure the included slicer software supports dual extrusion and is user-friendly. Tools like Cura, PrusaSlicer, or Simplify3D are popular choices that offer detailed control over dual extrusion settings.

5. Leveling and Calibration

Dual extruders require precise calibration to prevent oozing and misalignment. Look for features like automatic bed leveling, nozzle offset calibration, and wipe and prime towers to ease the process and improve print quality.

6. Price and Warranty

The price for dual extruder printers varies widely, from budget models under $500 to high-end professional machines above $3000. Consider your budget and also look for solid warranties and responsive customer support.

Recommended Use Cases

Dual extruder 3D printers excel in several fields. Here’s how different users can benefit:

- Designers and Artists: Create vibrant prototypes with dual-color or gradient filament blends.

- Engineers: Print complex parts with soluble supports for intricate geometries.

- Educators: Demonstrate advanced fabrication techniques and material combinations to students.

- Small Businesses: Accelerate product development with functional multi-material prototypes.

Popular Dual Extruder Models

Here are a few dual extruder models highly rated by the 3D printing community:

- Raise3D Pro2: Precision-focused, high-performance machine, excellent for business users.

- FlashForge Creator Pro 2: Budget-friendly with IDEX design, great for newcomers.

- Bambu Lab X1-Carbon: Advanced features like AI monitoring and fast speeds, perfect for prosumers.

Final Thoughts

Choosing the right dual extruder 3D printer comes down to understanding your specific goals, budget, and technical needs. Whether you’re looking to craft artistic prints with vivid dual colors or manufacture parts with soluble support material, the correct machine will significantly enhance your 3D printing capabilities.

Take your time comparing features and try to see real-world user feedback before making your decision. With the right dual extruder 3D printer, your creative possibilities are virtually limitless.